Applications and Implications

individual project:

Propose a final project masterpiece that integrates the range of units covered,

answering:

What will it do?

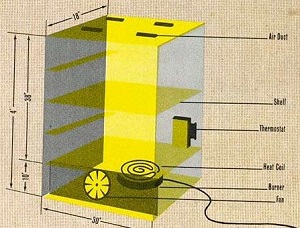

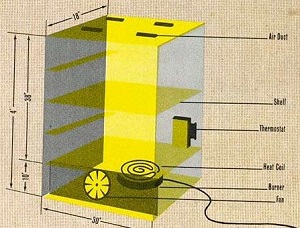

It will be drying perishable foods by exposing them to certain degree of temparature

My project revolves around food science. How well can we conserve food especially perishables to stay for long.

The idea was to come up with a method of storing food and as well coserving them for longer periods of time.

Who's done what beforehand?

I didn't find a topic exactly related to my project but I have found

a lot of useful articles to help designing and implematation.

expecially to the heat elements.

What will you design?

Am responsible for designing all the electrical and housing for it, beginning and desisigning the casing for it

where the electronics will be to the place where the food will be handled

What materials and components will be used?

I have listed whats needed in my final project page which is as below:

Heating element.

SPDT relay,

Alluminum foil tape,

Cooling fun

the list may change depending on the the findings found along the way

Where will come from?

Am planning to do most of the manufacturing at the lab

and what i cant make to source from the reliable sources on which mostly it will be electronics

from reliable electronic shops such as pixel electronics and nerokas located here locally.

How much will they cost?

My plan is to do a bill of materials and share in the final project page keeping in mind

that the cost of production and sourcing should as low as possible.

Heating element: $30

SPDT relay: $3

Aluminum foil tape: $40

Cooling fun: $1.5

Display: $6

copper wire: the intension of this is to build my own heating element.

Pricing: $10

Alluminum sheet: $35

connection cables: $10

Heating element: $30

SPDT relay: $3

Aluminum foil tape: $40

Cooling fun: $1.5

Display: $6

copper wire: the intension of this is to build my own heating element.

Pricing: $10

Alluminum sheet: $35

connection cables: $10

What parts and systems will be made?

The whole housing for the dehydrator will be made from the lab and some of the

electronic based parts.

What processes will be used?

Metal workshop for curving metal parts and either making hinges

3D printer for printing plastic parts of the casing

Vynl cutting for cutting out labling

CNC milling for the larger wood frames where possible

PCB milling/electronics design where possible

What questions need to be answered?

How will I design the PCB boards for each display and how will they communicate with

how will the casing look like and which materials will be appropriate for it

Can the display units be powered with same power supply

Is the Pcb design really necessary for the for the brains of the whole system

How will it be evaluated?

how was the intergrated done?

how was the circuit done?

how was the consumption of power managed

how was the casing decided at the end

The following part of the questions i decided to share a link of the final project page to avoid repetitive

some work already done

I decided to use this week of implementation to work on the final projects through applying

what i have learned through the whole time this are:

Your project should incorporate 2D and 3D design,

additive and subtractive fabrication processes,

electronics design and production,

embedded microcontroller interfacing and programming,

system integration and packaging

Where possible, you should make rather than buy the parts of your project

Projects can be separate or joint, but need to show individual mastery of the skills,

and be independently operable

but not limited to above.

You can see all the progress here for the entire project

have a look here

Back

Back